*We stand behind repairs with a 30 day GUARANTEE!

WHO DO WE HAVE USING OUR REFURBS?

COMMON CONCERNS

Customer Concern # 1 - Is it too heavy?

Two Identical CCM Ribcor 40K:

- New = 425 Grams

- Refurb = 449 Grams

In comparison:

- Ribcor 30K = 465 Grams

- Ribcor 28K = 515 Grams

- Ribcor 26K = 570 Grams

After refurbished our sticks remain among the lightest in the industry. You

will find repair weight is hardly noticeable.

Customer Concern # 2 - Disruption of the flex and kickpoint?

| Brand New | Refurb |

|

|

- Conducted on-ice testing with professional players (including accuracy and shot speed tests)

- Lab tested the sticks (took two identical sticks in all the top brands and tested a refurb vs. a new one on a flex profile testing machine)

- Both tests concluded the the flex profile and kick point of the shaft were not affected by the internal repair (down lower you will learn why)

Customer Concern # 3 - Strength?

- The reinforced section of the stick is a made from high grade carbon composite material that forms an internal bond with the shaft and makes it stronger in the repaired area.

- You SHOULD never have a stick break in our repair (warranty rate is approx. 1 percent)!

- We back it up with a 30 day guarantee!

How it works

HockeyStickMan uses a carbon fiber AirCore™ and Shaft-Lock™ Technology - a process used to prepare the interior wall of the shaft and "lock" the repair in place. The AirCore™ is comprised of 2 layers of carbon fiber surrounding a foam center, which allows the AirCore™ to conform to junior, intermediate, and senior shafts. Being concealed internally, Our repaired composite shaft repairs minimize visual disturbance and preserve the external shaft profile. In other words, they look and feel great!

Here is the HockeyStickMan refurb process, by far the # 1 solution in the industry:

Step # 1 - Sourcing

- We work with 140+ teams to bring in the latest and greatest makes and models

- Pro stock sticks are better quality, more durable and responsive

Step # 2 - Inspection

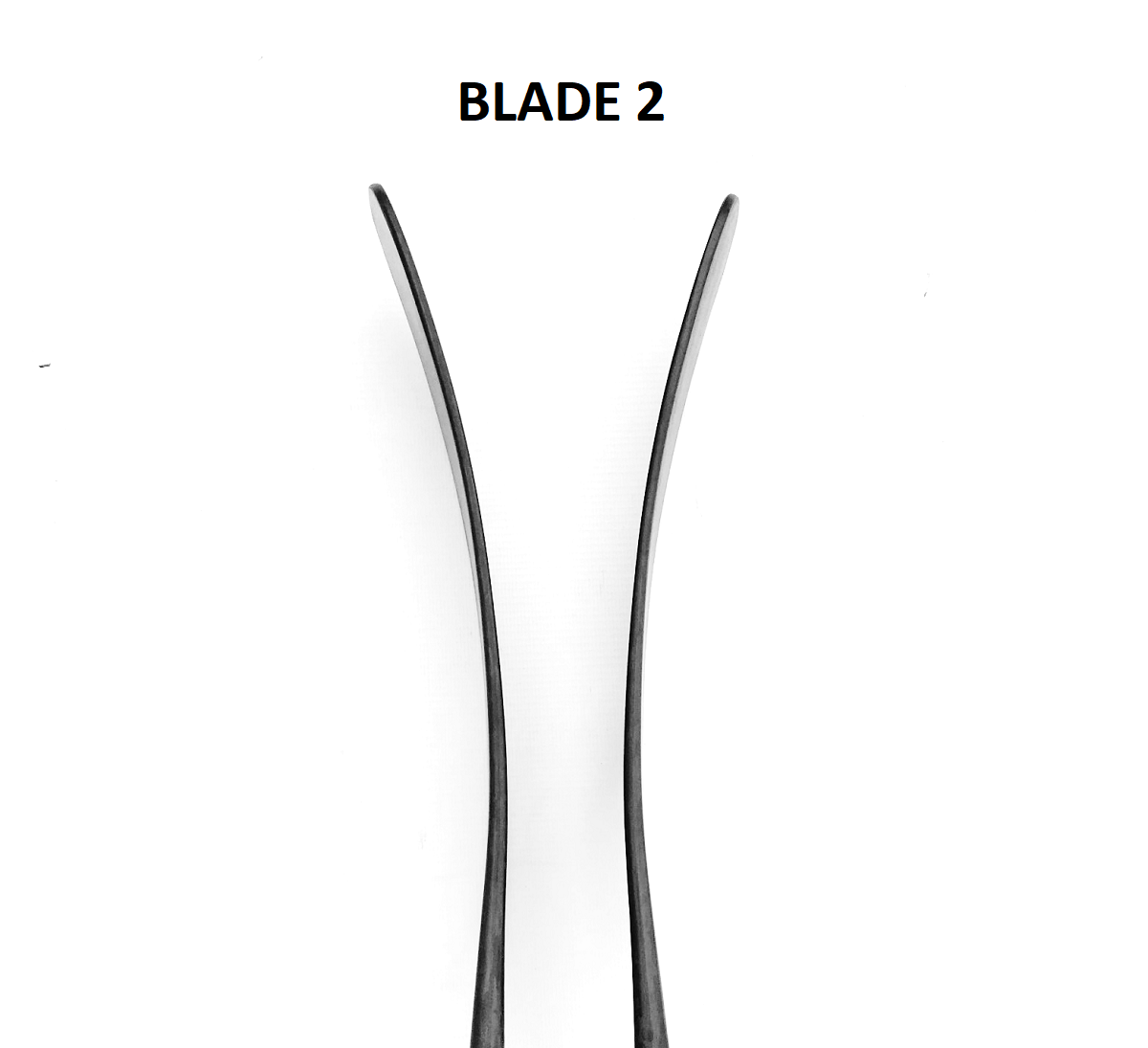

- We check all sticks for punky blades, chipped toes, and any micro fractures

- We only fix the ones that are in otherwise excellent condition

- Approx. 1/3 of what we get is selected for repair and resale

Step # 3 - Cutting and Beveling

|

|

|

|

Step # 4 - Alignment and Epoxy

- Insert a double wrap carbon fibre sleeve and align the two stick pieces

- A special combination of resin and hardener is poured down the shaft engulfs the carbon sleeve and forces the fibres into the grooves

Step # 5 - Curing and Cracking

- The sticks cure in the clamp for 72 hours in a temperature controlled room

- It is then "cracked" - we flex it out multiple times in both directions

- You will hear cracking sounds of the internal plug pulling away from the side walls while grabbing onto the groves. This enables it to return to its original flex and kick point

Testimonials

At $80-$110 for a $380 hockey stick you can't afford not to try one. But don't take our word for it, read customer reviews

Blade Repair

Please note that we no longer offer blade repair. We just feel that shaft repair is a much better solution.

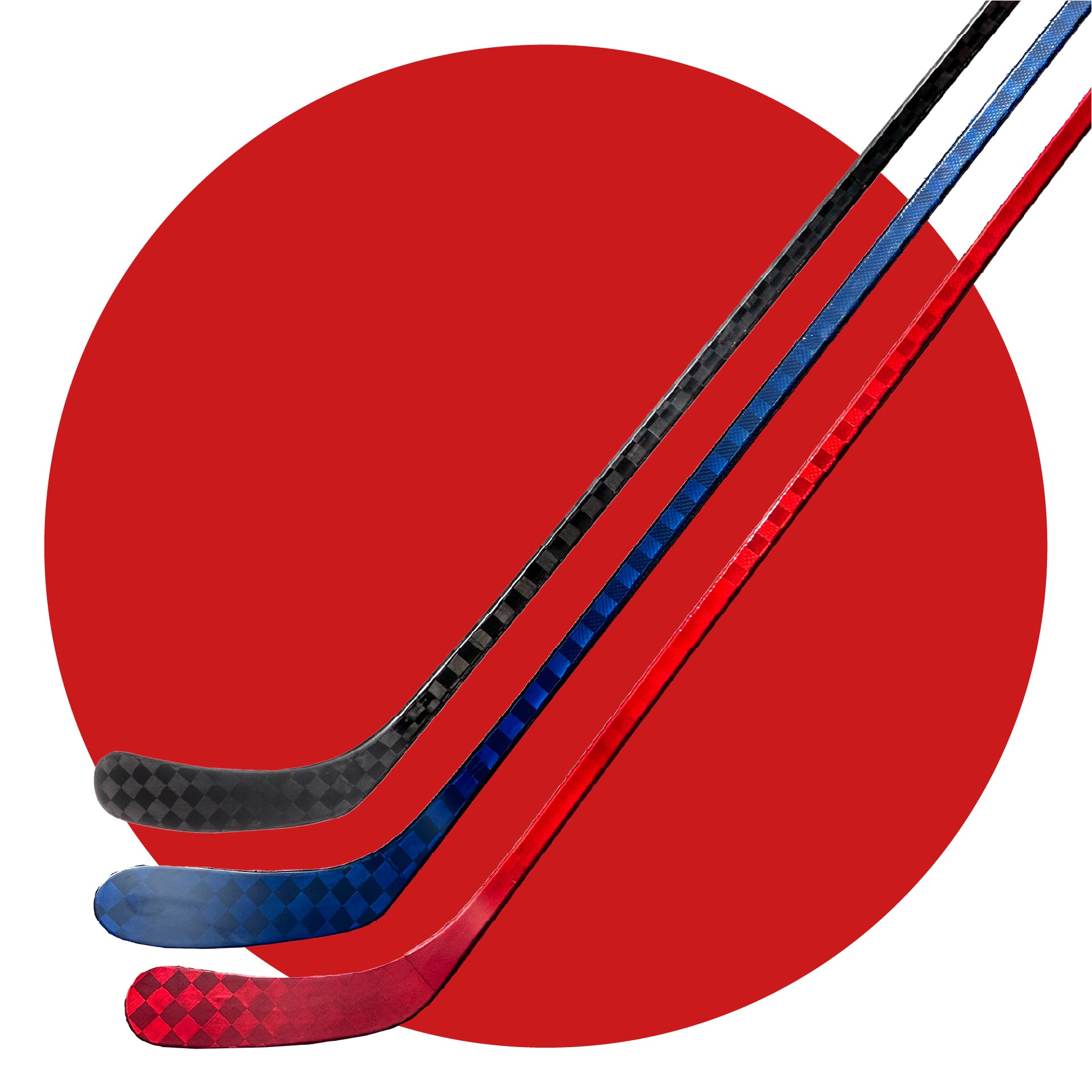

The Pro Blackout™ Series

Top end sticks, half the price. Shop the #1 selling stick at HSM.

Shop Pro Stock Sticks

Check out top of the line sticks for half the price